- New MAHLE system for cabin heating reduces energy demand for air conditioning in electric vehicles by up to 20 percent

- The result: more efficient climate control, greater range per battery charge and first-class interior air quality

- Heat energy is recovered from the cabin air, fresh air intake is efficiently preheated through exhaust air

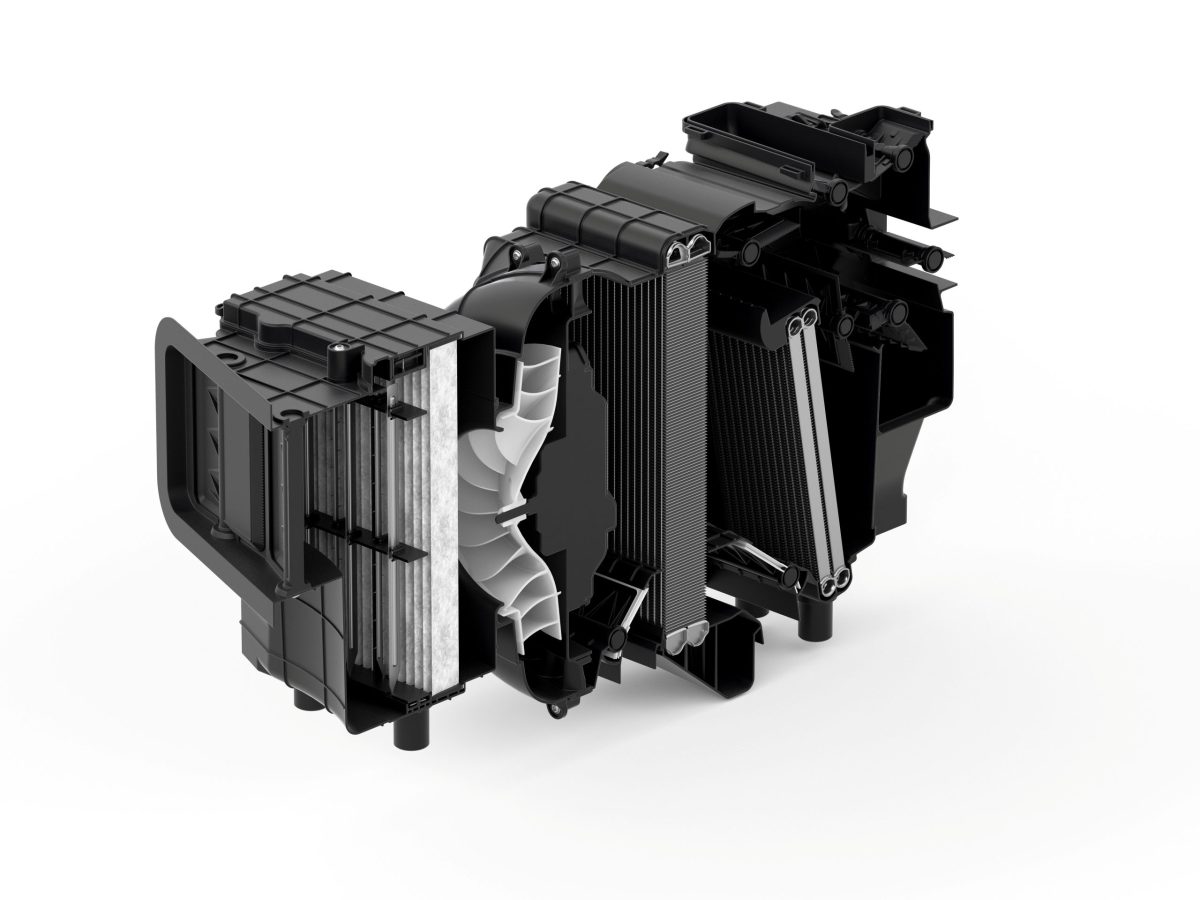

- Modular design enables simple and cost-effective system integration into existing vehicle architectures

MAHLE has developed an innovative heat recovery system for efficient cabin heating in electric vehicles. Heating has a significant impact on EV range, particularly during winter. MAHLE HeatX Range+ reduces the energy demand for air conditioning in electric vehicles by approximately 20 percent compared to conventional exhaust air systems. As a result, drivers benefit from extended range per battery charge and first-class interior air quality.

“Our HeatX Range+ heat recovery concept maximizes the everyday practicality of electric vehicles in winter and makes a decisive contribution to further increasing the attractiveness of electric mobility,” explained Martin Wellhoeffer, Member of the MAHLE Group Management Board, responsible for the business unit Thermal and Fluid Systems. Thanks to its modular design, manufacturers can easily and cost-effectively integrate the new system into existing vehicle architectures.

MAHLE has succeeded in extending driving range by nearly 10 kilometers with an innovative and economical solution – as testing with a typical mid-size electric vehicle at an outside temperature of -7°C and an interior temperature of 20°C demonstrated. At the same time, the continuous supply of oxygen-rich air ensures high interior air quality and minimizes the risk of fogging on vehicle windows.

The new heat recovery system uses the air conditioning evaporator to extract and utilize heat energy from the vehicle cabin’s exhaust air. As the air directed outside passes through the evaporator, it heats the refrigerant while leaving the cabin. The refrigerant then transfers the stored energy to the fresh air intake before it enters the vehicle interior. This efficiently preheats the fresh air and reduces heating power demand at winter temperatures compared to conventional exhaust air systems.

The new heat recovery system has no adverse effect on the air flow performance or acoustic behavior of the vehicle air conditioning system. In implementing this innovative energy recovery technology, MAHLE drew on its extensive experience developing and manufacturing vehicle climate control systems.

“As early as the 1990s, MAHLE introduced the ‘Economizer’, the first cabin heat recovery system concept for passenger and commercial vehicles, thereby pioneering today’s trend toward efficient cabin climate control,” said Dr. Uli Christian Blessing, Vice President R&D Thermal and Fluid Systems at MAHLE. The current heat recovery layout is designed for refrigerant R1234yf and can be adapted to all alternative refrigerants with only minor modifications.